![Header [TITLE]](/includes/image.php?width=1024&height=768&cropratio=3:2&image=/images/Anwendungen-Headerfoto.jpg)

Medical products

Specialised semi-finished products by ER&GE are suitable for many different uses within the medical sector. Our plastics boast hygienic advantages and a wide range of properties

Animal Elizabethan (Buster) collars

After an operation, animals are particularly at risk of infection when they lick their wounds. In order to prevent this undesirable animal behaviour, Elizabethan collars are used temporarily. ER&GE provides the base material for such products. This material is a 0.6 to 1mm thick embossed film made from transparent, unadulterated random copolymer. The products are manufactured in different variations, for example corrugated or corona-treated in order to make them suitable for printing.

Splints for dental use

ER&GE manufactures the base material for a specialist supplier of dental products. The material used for circular plastic blanks, which are formed using heat over plaster models of patients’ teeth in a small thermoforming machine. What emerges is a transport container for brackets, which can thereby be used more easily. Moreover, the plastic dental imprint can also be used as a splint to protect against grinding. LDPE with a certain amount of HDPE ensures the desired rigidity and thermoforming capacity. A lubricant is applied to guarantee separation.

Furniture and household

As well as their excellent processing properties, ER&GE plastics also display good physiological compatibility. This is significant wherever people are handling personal items and food.

Chopping boards

The plastic sheets manufactured by us are designed to meet HACCP control standard in the catering trade. Accordingly they are colourfast, food safe and especially easy to clean. Moreover, they do not wear easily. We manufacture polypropylene boards with a thickness of 2mm, which can be processed and made into hygienic chopping boards of different sizes and colours.

Table sets

Brightly coloured table sets should preserve their decor for as long as possible. We use 0.6mm thin, corona-treated plastic with a pearl structure underneath. This printing preparation process ensures improved colour adhesion properties. Not only do the sets look good, but they are easier to clean and are more durable.

(image currently not available)

Drawer inserts

If you put loose items in a drawer, they move about easily when you open and close it. This results in scratched surfaces and items which are difficult to find. ER&GE has produced a plastic film for kitchen manufacturers that offers protection. A co-extruded material with an especially grippy surface ensures that the bottom surface is directly protected and that the items can no longer move about uncontrollably.

Water protection systems

From 0.8 cm thick PP film, ER&GE manufactures a base product for the Scandinavian market, which is processed further and used as a household item. In Scandinavia, many kitchens are fitted with wooden floorboards. Consequently, many insurance policies make it a condition that protection against dripping water is put in place, for example, as soon as a washing machine is installed in the kitchen. As protection against leakages from the machines, pipes and outlets, the company now offers a collapsible PP product that collects escaping water. The component can be collapsed to the desired size and is also suitable for use underneath the kitchen sink unit.

Storage technology and packaging manufacturers

People working in logistics are interested in stability, safety and intelligent solutions when storage technology and packaging is concerned. With our semi-finished plastics, ER&GE makes a significant contribution to the entire packaging concept.

Transport and storage boxes

Injection-moulded containers for small load carriers are used in all areas of logistics. In certain cases, ER&GE provides a heavy duty plate that is welded to the underside of the box. This re-enforcement adds strength to the box and significantly increases durability.

Runners for H1 plastic pallets

In order to secure packaged goods with good pallet stability, the runners on H1 plastic pallets are strengthened with our plastics. The sheet, which is 5mm thick and furnished with an optional non-slip layer, is permanently attached to the pallet via a vibration welding process. A further advantage is that it cannot be penetrated by dirt. Its application is implemented with mill-finished and non-slip polyethylene.

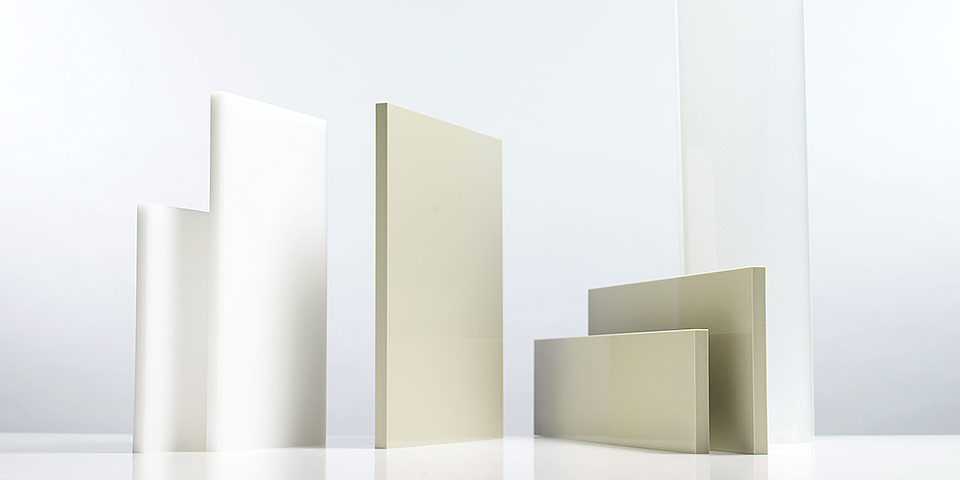

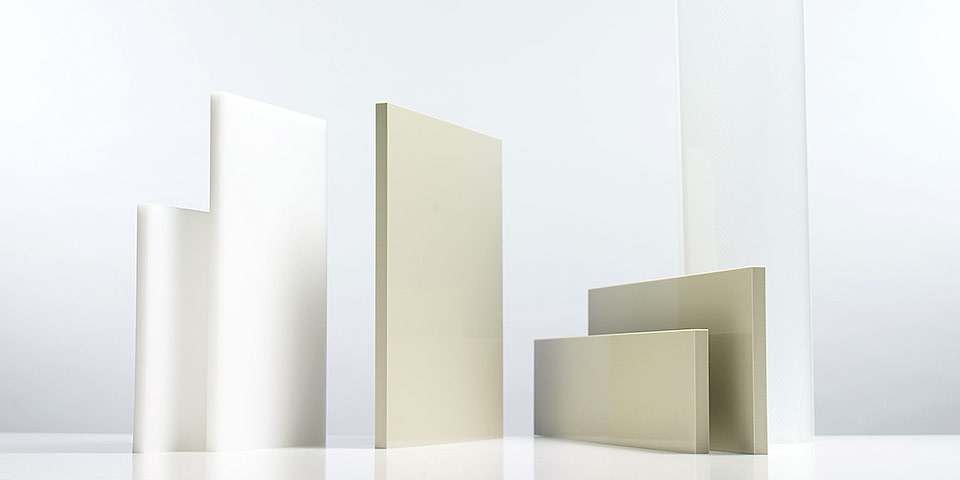

Manufacturing of chemical apparatus and tanks

The manufacturing of chemical apparatus and tanks is a classic area of application for extruded sheets made of PP and PE-HD. Due to their diverse chemical resistance levels, our semi-finished products are perfect for use as base materials for different containers.

Tanks for water treatment

Our semi-finished sheets are suitable for all the usual treatment processes. The materials are free from heavy metals and are physiologically harmless, making them suitable for use with drinking water.

Various containers

ER&GE provides semi-finished plastics for areas of application with exacting hygiene standards. They can also be used in other industries, for example for pressure tanks in the chemical industry, mixing vessels in the pharmaceutical and food industry, cooking and refrigerating containers, tanks for storage or transport, CIP vessels, rundown tanks and much more.

How PE-LD and PE-HD respond to chemicals

More information on the chemical resistance of our semi-finished products are available for download here:

Automotive suppliers and vehicle manufacturing

Semi-finished products by ER&GE are used in the manufacturing of many different vehicle components. These include moulded and stamped components from semi-finished products and bi or trilaminates made from composite material. ER&GE possesses the expertise and production capability in both areas.

Thermoformed moulded parts as heat shields for fuel tanks

ER&GE was selected as a supplier of extruded PE-HD sheets. As well as using the same raw material that the actual fuel tanks were manufactured from, we fulfilled the high tolerance requirements for both the extruded sheets and the thermoformed moulded parts.

Car interior bilaminate

Here, plastic and carpet are bonded thermally and mechanically. In doing so, there is a specific requirement: preventing visible white breaks to the plastic in heavily shaped and moulded areas.

Structural engineering and landscaping

Weather resistance, robustness and environmental friendliness are just a few reasons to use sheets and films in the structural engineering and landscaping industries. Their clever use leads to environmentally friendly concepts with almost emission-free and structurally sound products.

Skirting protection

Wall protection is always a sensible option where large and heavy objects are moved via rollers, for example with trolleys in shops or beds in hospitals. So that walls do not constantly need to be cleaned or re-painted, protection strips are fitted which, for example, are made from 10mm thick polypropylene with a matt surface. As well as the strips having high impact strength, there is the added advantage that they can be manufactured in any colour of the client’s choosing.

Privacy screens

Made from ER&GE plastics, these privacy screens for metal grid fencing are a real alternative to similar PVC products. In terms of opaqueness, UV resistance and weather resistance, the material is the equivalent, at the very least. Being low-weight, polypropylene comes with the added cost advantage over PVC. Not to mention environmental reasons: if the palisade ever catches fire, no dioxins or hydrochloric acid gas will be emitted.

Rhizome barriers and root protection

There are specialist products to prevent the uncontrolled expansion of growing roots, such as bamboo, or to protect cables and pipes in the soil from penetrating roots. ER&GE manufactures the base product – rolled material from which the required size can be cut. Standard dimensions are 1.3m in width and up to 500m in length. This product is available in the classic colour spectrum, such as muted shades of green and brown or black, and also RAL colours or any other desired colour.

Use within the agricultural industry

Whenever the production of foodstuffs is concerned, strict rules are in place regarding hygiene measures. The advantages of polypropylene and polyethylene are obvious – they ensure that high environmental and animal welfare standards are kept. At ER&GE, we guarantee this same food production standard in our manufacturing processes. This keeps germs outside of where animals live.

Feeding systems

Feeding systems have become an integral part of animal farming technology. It is clear that people wish to benefit from the hygiene and cost advantage of polypropylene. ER&GE makes its contribution to the load-bearing structure made from polypropylene sheets. These are welded to troughs that are equipped with a feed mixer. The animal presses against the device as it leans in to feed, automatically releasing a mix of dry food. A 6mm strong, naturally coloured and mill-finished material is used for the troughs, which minimises contamination.

Hygiene features for animal farming systems

One challenge in chicken farming is the removal of excrement and faeces. ER&GE manufactures rolled material for a specialised agricultural supplier, which acts as a conveyor belt within the barns. The sheets are between 0.5 and 1.2m wide and up to 300m in length and are used to collect and remove excrement. The stain and dirt-repellent properties of polypropylene come into their own. The use of basic reground materials in the manufacturing process makes the solution particularly cost-efficient.

Machine and plant construction

With plastics from ER&GE, many applications are possible. Our range of special products, such as antistatic or electrically conductive designs, can also be used in additional areas of application.

Gaiters

Gaiters are used to protect moving machine parts from external contamination such as sawdust, dirt and dust. These are usually made from textiles, moulded plastic or rubber. We use a grained PP film that one would normally expect to see within a range of office items. The 0.7mm thick, translucent film material is grooved and has that classic concertina appearance. This product combines good performance with an attractive visual appearance.

(image currently not available)

Manufacturers of palletable containers

Solid plastic layer pads are used for the transportation of palletised containers, such as glass and PET bottles, jars and beverage cans.

Layer pads

Since the early 80s, ER&GE has been a pioneer in this area, and has concentrated on the sale of this reusable packaging for the automated stacking of containers on pallets. At ER&GE, manufacturing is designed with food safety standards in mind.

You can find further details about layer pads here.

![ER&GE - Customised PP | PE [Logo]](/assets/logo-claim-2015.png)