![Header [TITLE]](/includes/image.php?width=1024&height=768&cropratio=3:2&image=/images/Qualitaet-und-Umwelt-Headerfoto.jpg)

Quality and environment

Measurable results

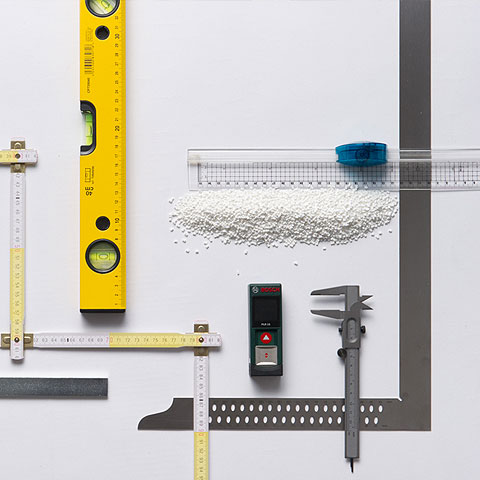

The quality of our products is based on the adherence to applicable norms, internal standards and test protocols. We go to great lengths to ensure excellent product quality during the manufacturing process:

- Exact following of client and product-related raw material recipes via system-controlled weighing and dosage systems

- Archived product-related process parameters

- Inline colour measurement for each selected colour

- Continuous checking of product dimensions and quality features

- Preventative maintenance of manufacturing plants and equipment

- High levels of staff competency

- Systematic training and continuous professional development

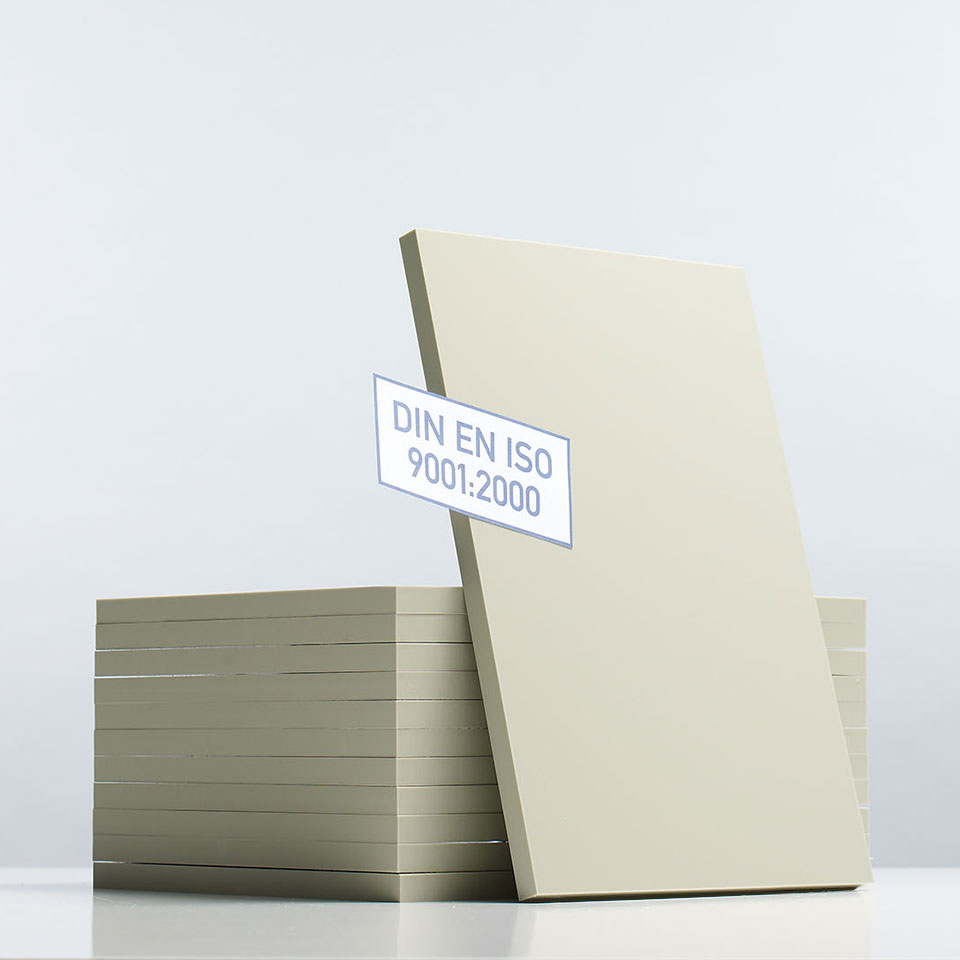

Certified quality

In 2005, ER&GE was certified for the first time according to DIN ISO 9001:2000 and was successfully re-certified to DIN ISO 9001:2008 in 2020.

Assessment by an independent body has many advantages for you:

- A standard with a high level of acceptance

- Consistent quality assurance

- Measures for your individual products which build confidence

- Cost saving: you don’t have to carry out cost-intensive audits

- Personal responsibilities are regulated

As well as a high amount of client focus, we continuously strive to improve our processes and products.

Download the certificates as PDF files here:

DMSZ Certificate – ISO 50001

DMSZ Certificate – ISO 14001

DMSZ Certificate – ISO 9001

Environmentally responsible

Economic use of energy

As an energy-intensive company, ER&GE is governed by legal guidelines and also our own claim that we maintain effective energy management. As part of our work towards our successful certification in 2014, we introduced active management of all internal plants and equipment. We make great efforts to explore new technical solutions, new technologies and areas for future optimisation, which may be developed and introduced within operations, as a permanent energy-saving concept. In other words, we aim to reduce energy consumption by analysing our own situation and discovering potential improvements, such as more efficient motors or propulsion technology. Therefore, in summer 2015 we equipped an extrusion line with new, ‘state of the art’ control technology and high efficiency drive motors.

ER&GE understands living energy management to mean finding opportunities for improvement, such as air conditioning in the administration department. It was changed from continuous operation to time-controlled with a reduced running time, so that its energy consumption could be halved. Further energy saving potential lies within reducing operational times of cooling compressors, replacing lights and turning off machines that are left idle for long periods of time. Last but not least, energy management is a question of support from the employees within the company. At ER&GE, all employees are trained and familiar with the principles of responsible energy use.

REACH: ER&GE plastics do not need to be registered

The European chemicals regulation, REACH, which covers the registration, evaluation, authorisation and restriction of chemicals, came into force on 1 July 2007, with a view to protecting the environment and people’s health.

The regulations require all manufacturers and importers of substances of more than a tonne's worth of annual production that fall within the ambit of the regulations, to register the said substances before they are imported or released. All substances requiring registration must be registered with the specially created REACH body ECHA (European Chemicals Agency) in Helsinki.

Polymers such as PP and PE however, do not fall within the ambit of REACH. Consequently, none of ER&GE's products are affected by the REACH regulations.

Nevertheless, as a precautionary measure, ER&GE is currently testing the fillers that are added to our polymers in order to achieve specific product characteristics, such as pigments and flame protection agents. We do not however, anticipate any fundamental changes in terms of mandatory registration. Should the certification of any of our materials change at a later date, we will of course, inform our customers without delay.

For more information on REACH, go to www.reach-clp-biozid-helpdesk.de (available in English)

![ER&GE - Customised PP | PE [Logo]](/assets/logo-claim-2015.png)