![Header [TITLE]](/includes/image.php?width=1024&height=768&cropratio=3:2&image=/images/Unternehmen-Headerfoto.jpg)

The Company

Semi-finished plastics according to the client’s needs

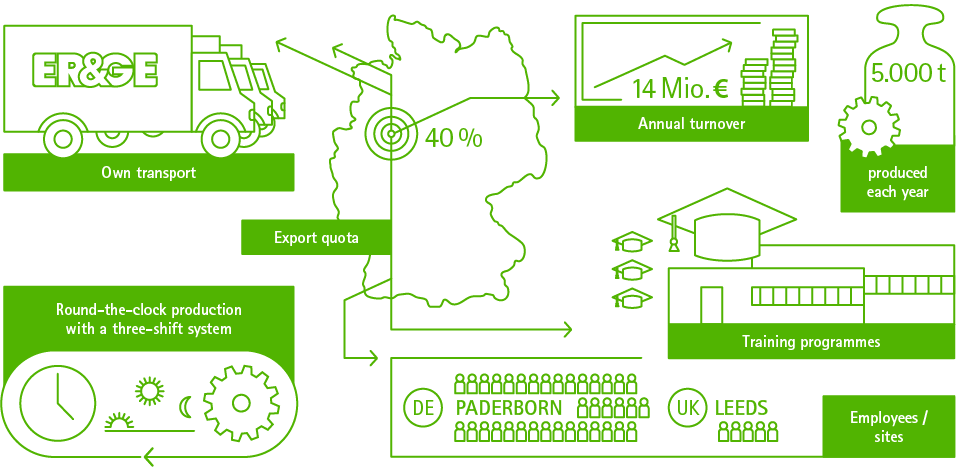

Specific tasks require solutions that are more than standard. ER&GE offers its clients semi-finished plastics which are tailor-made for these challenges: customised PP/PE. In other words, extruded sheets and rolls – for printing, forming, mechanical processing, lasering, fabrication, adhesion or welding. Not only does ER&GE supply the material, but we are frequently involved in project development and work with our clients to find a common method of creating the finished product.

As an independent manufacturer of customer and application-specific extruded sheets and film made from polyolefin, as well as plastic layer pads, we have found our market mainly in Germany and Europe. Our British subsidiary in Leeds carries out the sale of goods manufactured in Paderborn for the UK market and has a range of standard products in stock.

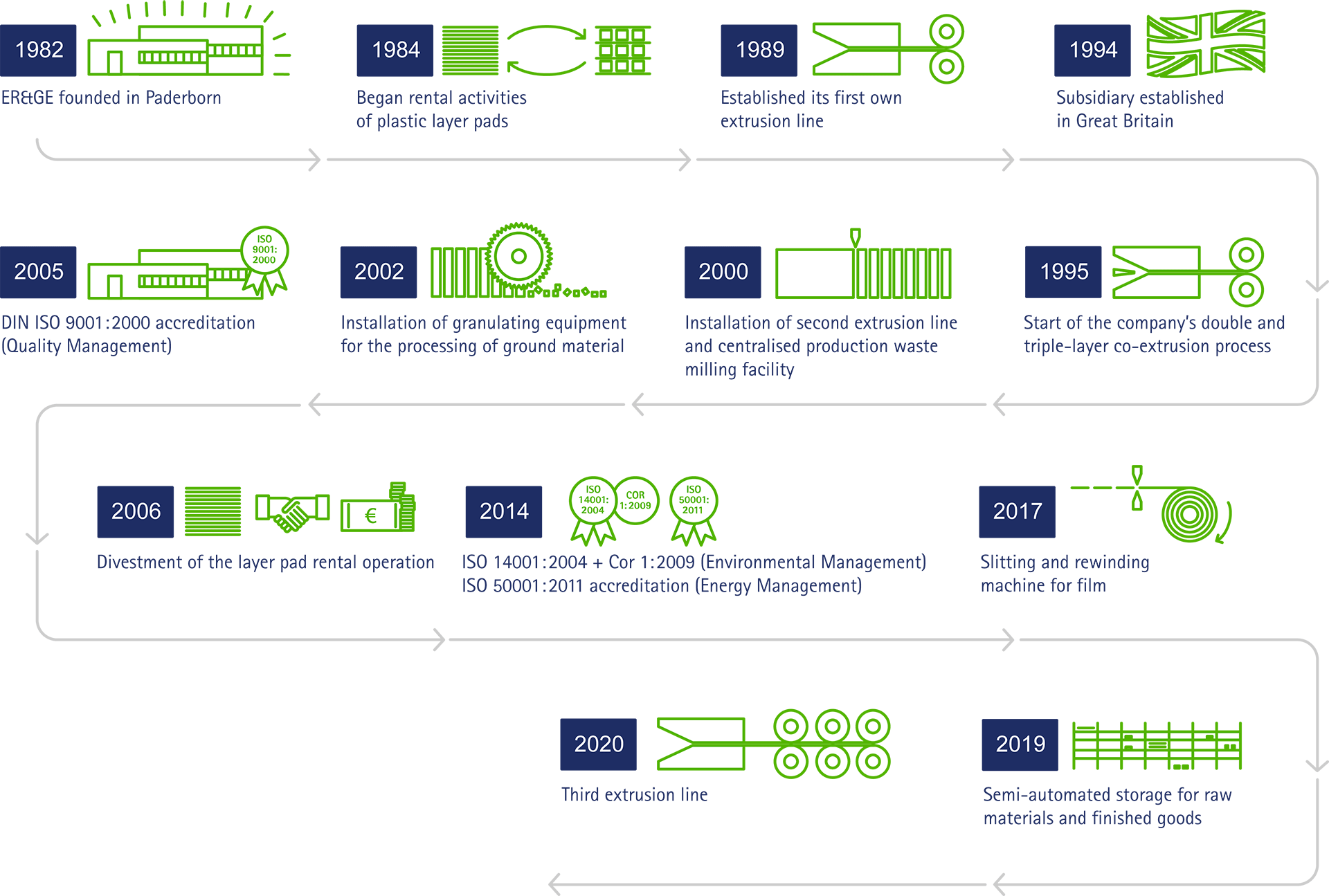

From a supplier of layer pads to a specialist manufacturer of semi-finished plastics

ER&GE began trading in 1982 with the processing of purchased plastic sheets into layer pads. These were at the heart of a hygienic re-usable transport logistics system for the packaging of glass containers and beverage cans, as a replacement for the previously used disposable cardboard packaging. Below is a breakdown of how the company has developed into its current status as a world class manufacturer of premium quality extruded sheet products:

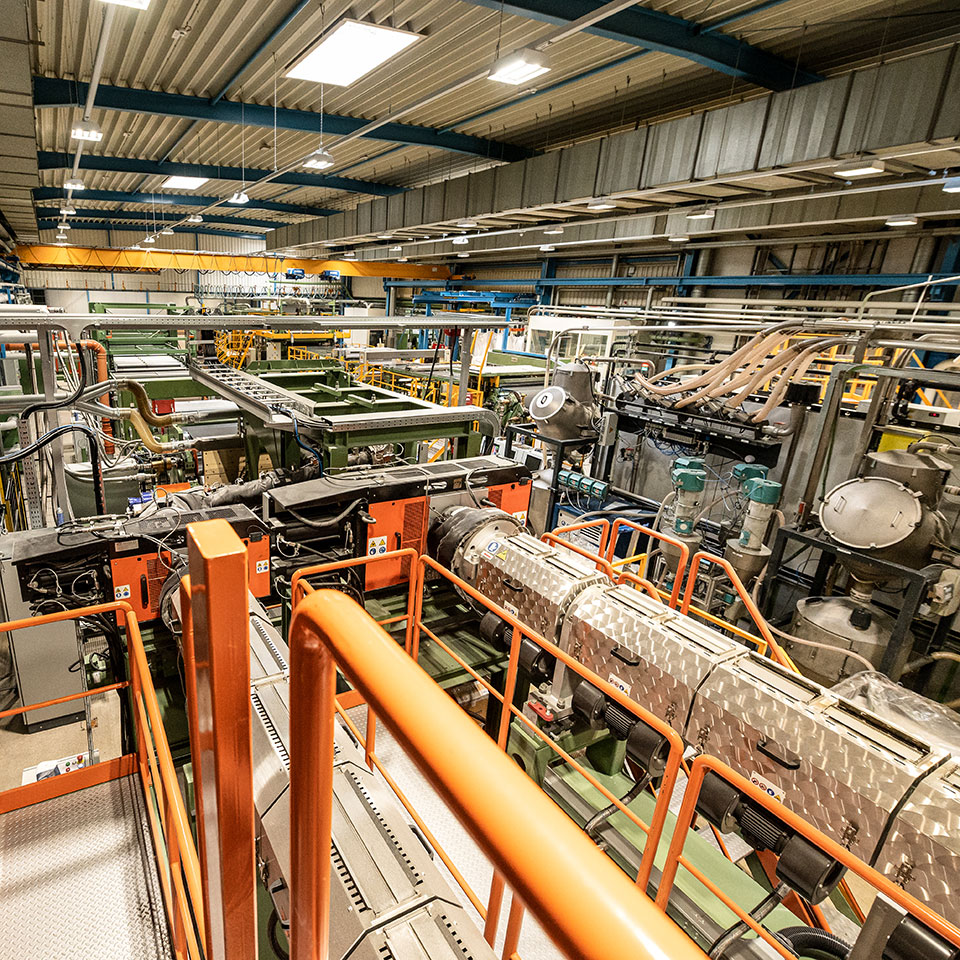

Cutting-edge technology

ER&GE is located in the Mönkeloh industrial zone of Paderborn. Production and storage areas as well as our administration are located here. We store the most common types of raw material in our material silos. These are processed using three extrusion lines into sheets and rolls of polypropylene and polyethylene, designed for the flexible manufacture of customer-specific products.

ER&GE produces completely in-house. We are fully equipped with all the technical facilities required for grinding, reprocessing and compounding of raw materials. Almost all production waste is recycled and reused in-house.

The processing department manufactures finished products using our extruded semi-finished materials.

Established, versatile and non-bureaucratic

From our point of view, high and consistent quality, as well as good service, are the best marketing steps.

Timely planning and consultation enables us to guarantee a high standard of quality with simultaneous and swift project handling. Our advisors establish the operating parameters and processing conditions for the desired project. Test productions lead over to later series production.

We operate our own transport logistics supported by selected third party providers. This helps to ensure that the goods reach you on time and in good condition.

![ER&GE - Customised PP | PE [Logo]](/assets/logo-claim-2015.png)