![Header [TITLE]](/includes/image.php?width=1024&height=768&cropratio=3:2&image=/images/Produkte-Headerfoto.jpg)

Finishings

Safer, more colourful and more resistant.

The perfect way to finish a product.

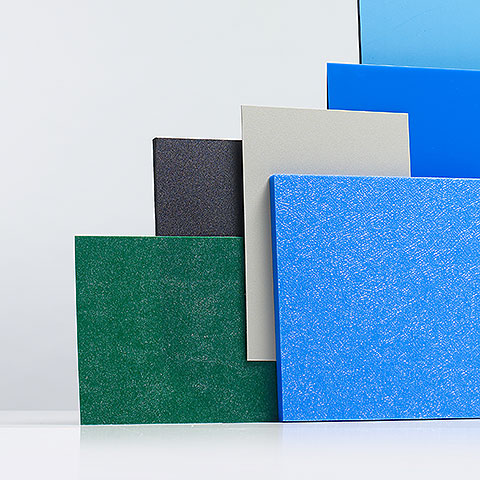

Surface – high-gloss, matt, heavy and fine leather embossing, pearl structure, square embossing, calendered, corrugated

UV resistance – effective for five or more years, depending on the product

Hot embossing – for individual commercial labelling

Electrically conductive – for example, for packaging electronic components

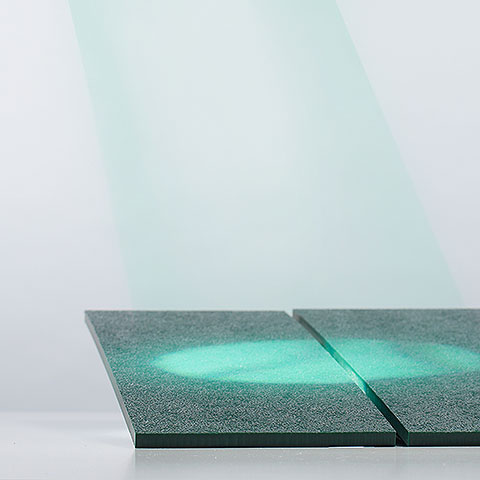

Anti-fog – important, for example, in vehicle interiors

Filler materials – chalk, talcum, natural fibres

Shock resistance – shock resistant up to -23 °C

Anti-static equipment – prevention of electrostatic build-up

Thermal stabilisation – reduces material disintegration at high temperatures

Corona treatment – for printing and adhesion

Lubrication – stops materials from rubbing together and makes them slide more easily – good for automation

Flame-retardant – meets international standards

Anti-block – reduces adhesion strength

Anti-slip – dull surface minimises slip of items applied

Polar cut – very form-exact, right-angled cutting for formats ranging from A4 to 1.50 x 1.50 m

Flexography – for the application of endless printing

![ER&GE - Customised PP | PE [Logo]](/assets/logo-claim-2015.png)